Leading the Way in

Heat Treatment Solutions

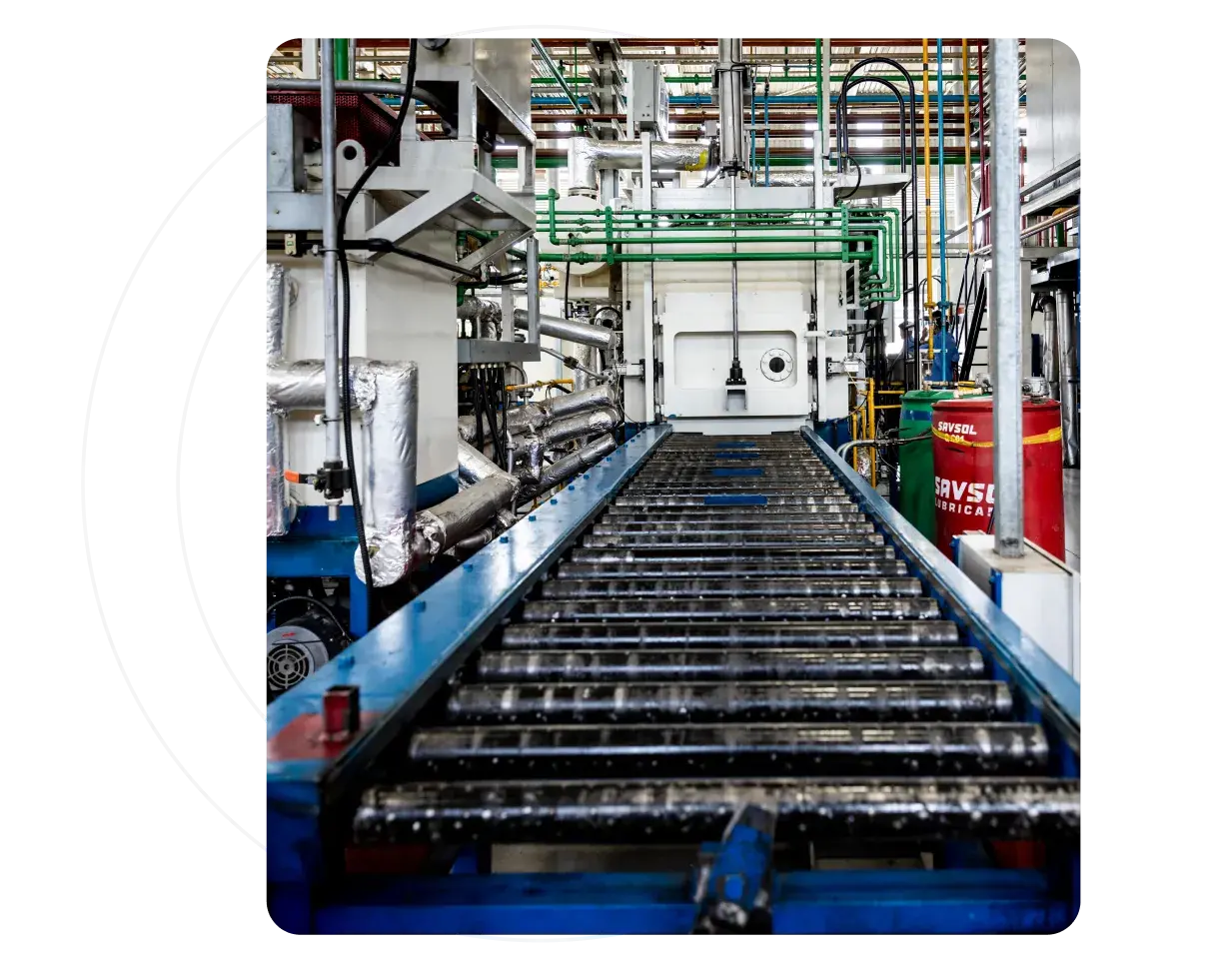

Incorporated in 1970, HIGHTEMP a subsidiary of Dowa Thermotech Company Ltd, Japan, has

grown steadily from building small ovens and industrial furnaces to becoming one of

India’s leading manufacturers of Heat Treatment Furnaces.

At HIGHTEMP, we prioritize excellent management practices, strict adherence to global

regulatory standards, and a steadfast commitment to efficient manufacturing processes.

Quality is the cornerstone of every product, process, and service we offer.

As we step into a new decade, HIGHTEMP is poised to expand its product and service

offerings and explore eco-friendly ventures like renewable energy, reflecting our

commitment to a greener planet.